The enterprise WMS solution for growth.

Gain control of your warehouse with Pinpoint WMS.

Anything that causes delays on the floor is a threat to your warehouse’s overall performance. That can include misplaced, unsorted, unlabelled inventory, and more. A WMS should solve these problems with ease.

Only a fully mapped-out warehouse, combined with paperless processing, can help distributors attain accurate and timely delivery of customer orders, pinpoint precise inventory counts and placement, and improve customer satisfaction. Pinpoint WMS is the backbone of productive warehouses.

Transform your operations with Pinpoint

We build our solutions around your business. Pinpoint supports traditional single order picking, “zone-based” picking and “pick and pass” methodologies.

Reduce Errors

Manual tasks lead to errors, and mistakes are expensive to fix. Pinpoint WMS automates and streamlines your processing to pick, pack, and ship the right product at the right quantity.

Maximize ROI

Does your warehouse suffer from wastage, misplaced stock, and shipping errors? Pinpoint WMS reduces these inefficiencies and streamlines order fulfillment.

Grow Paperlessly

Using RF-based or mobile devices, Pinpoint can move your warehouse to a paperless operation and eliminate the complexity of inventory management. More of your potential customers are demanding environmentally friendly partners. Using RF-based bar code terminals or kiosk computers, Pinpoint WMS can transform your warehouse to a paperless operation while eliminating complexity in your inventory management.

How Pinpoint Helps You

CFOs: Maximize space & make room for investment.

To reduce operating expenses and costly inefficiencies, you need deeper insight into your company’s warehouse floor.

When you choose the right WMS with enhanced warehouse visibility, you reduce your on-hand inventory and space costs. Ultimately, you will cut the costs of your operations without sacrificing quality. With Pinpoint WMS, can accurately track, find, and move low-turnover inventory.

CEOs: Meet customer demands & grow.

Customers expect quicker shipping and unflinching accuracy from retailers. By integrating with order fulfillment, shipping, and carrier management systems a robust WMS can help you cut your business’s shipping times.

Warehouse Managers: Eliminate error & empower your workforce.

A warehouse manager carries immense responsibility. You’re meeting with shipping carriers, purchasing and sales representatives while managing receiving, handling, storage, distribution and transportation… and are expected to have the solutions.

Reduce downtime while improving staff efficiency and productivity by utilizing RF technology and a streamlined pick-path. Our WMS software can get you there.

Features

Optimized Receiving

Pinpoint WMS’s receiving functionality is built to support rapid receiving using various devices:

- RF & Mobile device technology: flexible receiving procedures allow users to walk around a pallet, entering quantities as they are scanned

- Terminal with a scanner: similar to RF technology but uses a fixed workstation

- Serialized products ASN receiving integration

- Multiple warehouse transfer functionality allows the transfer of product from one Pinpoint location to another Pinpoint location

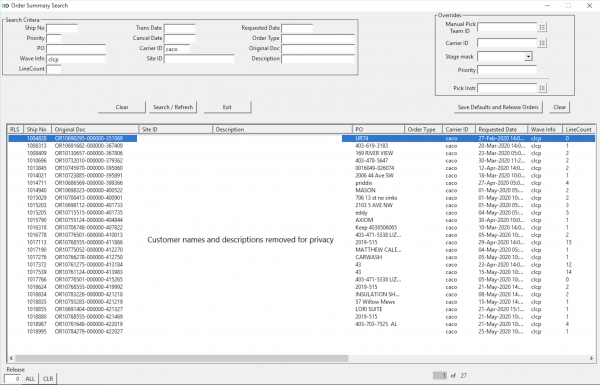

Task Management

Assign the most effective task management by using zone, wave, pick and pass picking, batch processing and equipment restrictions, reducing the number of steps necessary to complete a task.

Flexible tasking methodologies that – based on your facility – can be configured to optimize the pick order / path / operator and allow multiple order picking. We can help you determine the best ways to achieve efficient operator assignment / reassignment reflective of the roles they are assigned. Pinpoint can override order assignment when you need your staff to perform ad-hoc tasks. Primary picking locations can be identified for internal replenishment.

Shipping, Labelling, & EDI Support

Pinpoint WMS’s shipping functionality allows packers to validate quantities picked to ensure accurate order fulfillment. Print labels, packing slips, shipping address labels, and more with ease. Pinpoint WMS’s Advanced Fulfillment works with Latitude for full EDI compliance (MH10 / UCC128) to electronically communicate the contents of a shipment.

Full Inventory Traceability

Keep track of warehouse inventory movement in real-time. Pinpoint WMS uses barcodes and lot/serial numbers for quick, accurate inventory movement and order completion.

Ready to make your warehouse work better? Download our free brochure.

Download Our Brochure

Fill out the form below to view our latest product brochure.

8 Warehouse Management Pains

You, as a skilled warehouse powerhouse, can stay on top of your operations with the right tools to help you overcome your workplace’s pain points. Do you know which pain points are your worst offenders?

5 Key WMS Considerations

Inefficient systems not only slow down operations and distribution, they rob your organization of growth potential, additional revenue, good employees, and customer satisfaction.